Overhauls: our speciality

In the last 25 years, engine overhauls have become Yerseke Engine Services’ top speciality. We carry out overhauls on board or in our modern yard in Yerseke. In consultation with the client, YES can also carry out overhauls abroad.

A second life

Caterpillar engines are designed so that they can gain a second life after an overhaul â€" even after very many operational hours. A Caterpillar engine can keep going for twenty years this way.

The YES overhaul

At YES, we understand that it's very important that you're not out of action for too long. That's why we're dedicated to getting you sailing again as quickly as possible. A complete overhaul is carried out by us in two to four weeks. That includes: dismantling, overhaul, test runs in the test facility, commissioning, proof sailing and measurements. As well as the speed, the quality of the overhaul is extremely important. In the last twenty years, YES has developed an approach to make sure that quality and speed go hand in hand.

Working method

The need for an overhaul varies per case. That's why we always come on board to inspect the engine thoroughly. We even inspect the inside of the engine with an endoscope. We then draw up an advisory report based on our findings. If it is time for an overhaul, we provide a quotation and a schedule. A schedule from YES is no empty promise. We do everything to ensure that the work is completed on schedule.

Three types of overhaul

YES provides three types of overhaul. Firstly, a 'top' overhaul which is carried out after the engine has reached 50% of its expected useful operational life (50% of operational hours). We always carry out this type of revision on board. After reaching its total number of expected useful operating hours, an engine should be subjected to an inframe or complete overhaul. An inframe overhaul can easily take place on board.

A complete overhaul will give the engine a new lease of life. This kind of overhaul usually takes place in our yard. All of the facilities are available to carry out the overhaul as quickly and as carefully as possible. Once it has been completed, the engine can be thoroughly tested in the test rig. The test rig helps us ensure your engine is in a perfect state when it is reinstalled in your ship.

Care

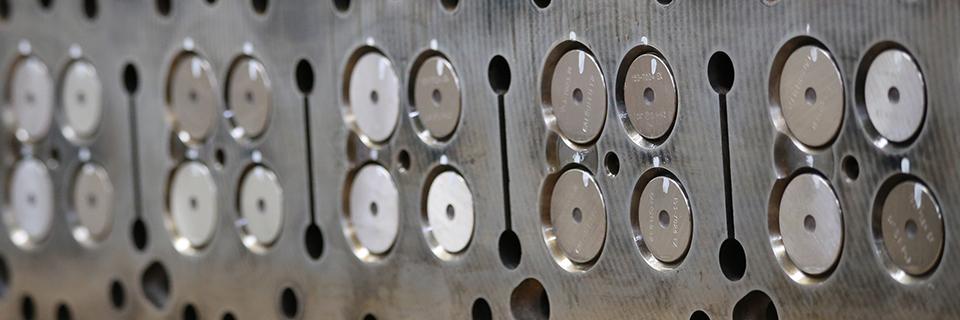

The quality of an overhaul depends on how carefully it is carried out. Once the engine has been dismantled, the basic elements are meticulously checked with the latest technology such as Infra Red and Magnetic Resonance Imaging. Most checks are carried out by YES itself and if parts have to be worked on we can do that ourselves. If the crankshaft has to be worked on - milling, grinding, planing or boring - we outsource it to our sister company, CF-Techniek. Both companies complement each other perfectly.

Testing

All overhauled engines are thoroughly tested by YES in our test rig. The circumstances on the ship are accurately reproduced. Thanks to these tests we can be practically certain that the engine will perform optimally once on board.